Business

HOME | Business | Molten Aluminum

Molten Aluminum

HOEI METAL is involved in corporate activities at all stages of the molten aluminum supply development, design and manufacturing processes that take the environment into consideration.

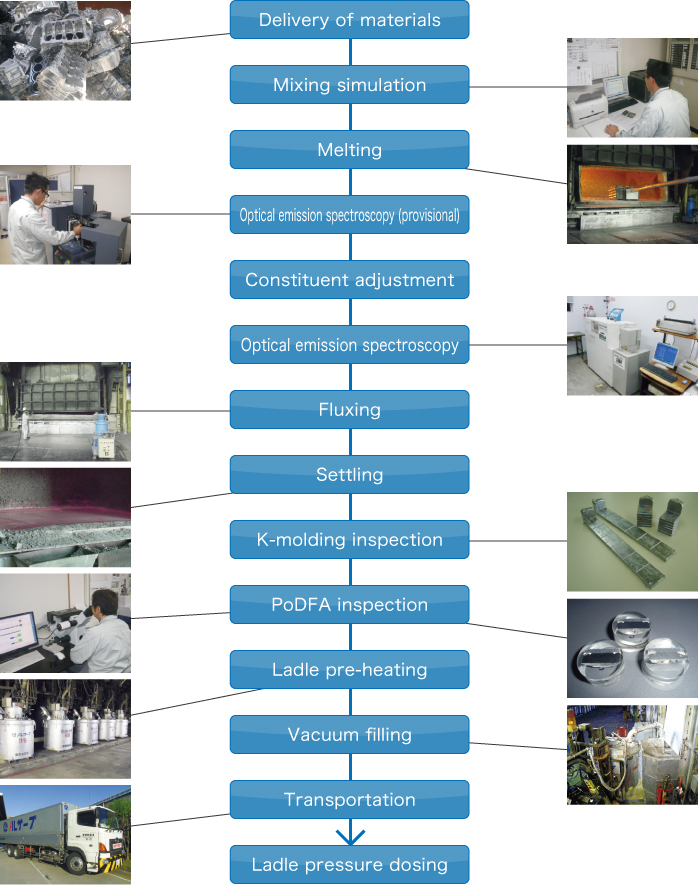

Molten Aluminum Process

Headquarters Plant Molten Aluminum Equipment

| |

1 |

|---|---|

| |

1 |

| |

2 |

| |

1 |

| |

2 |

| |

2 |

| |

3 |

|---|---|

| |

2 |

| |

1 |

| |

2 |

| |

1 |

| |

3,800 tons/month |

| |

ADC12 molten metal |

Tilting furnace

Molten aluminum only can be easily removed by tilting the entire furnace to retain scrap.

Immersion heater

Molten aluminum is shipped after adjusting it to the temperature requested by the customer using an immersion heater.

Burner heating machine

Cool Al Serve is preheated with a burner to enable transport.

Hekinan Plant Molten Aluminum Equipment

| |

1 |

|---|---|

| |

2 |

| |

5 |

| |

1 |

| |

1 |

| |

8 |

| |

5 |

| |

5 |

|---|---|

| |

1 |

| |

1 |

| |

1 |

| |

3 |

| |

7,900 tons/month |

| |

ADC12 molten metal ADS16 molten metal |

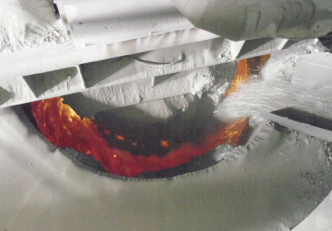

Smash melting furnace

Molten metal is rotated using magnetic fields, and chips fed into the furnace are melted immediately.

Rotary-kiln

Oil adhering to chips is treated before feeding the chips into the smash melting furnace.

Dross drawing machine

Aluminum is separated and squeezed from dross produced when melting the aluminum for reuse.