Technology

HOME | Technical Information | Vacuum Dezincification System

Vacuum Dezincification System

Vacuum dezincification system used to recover zinc and iron from galvanized steel sheet

Zinc is most commonly used for such automobiles and household products to prevent steel rusting, however, as with oil or natural gas, depletion is a concern. A significant quantity of zinc is used for galvanized steel sheet in particular, and therefore effective recycling is vital.

Our vacuum dezincification equipment is a revolutionary piece of equipment which utilizes the difference in steam pressure between iron and zinc. In a vacuum-processed furnace, galvanized steel sheet is heated to evaporate only zinc for isolation and recovery. In a vacuum-processed environment, zinc can be evaporated at a lower temperature than the boiling point of the material to facilitate energy saving.

In addition, since it is processed in a vacuum-processed environment, iron and zinc are not oxidized. Consequently, zinc of high purity can be recovered. Iron from which zinc was isolated is used as high-quality recycled material.

Equipment merits

(1) Fully-automated 24 hour continuous production from treated material loading to unloading Fully-automated 24 hour continuous production from treated material loading to unloading

Through technological development, our system allows zinc recovered inside the zinc recovery device to be unloaded during operation.

(2) Zinc removal capability: post-treated material (steel sheet shredder material) zinc plating constituent of 0.03% or less

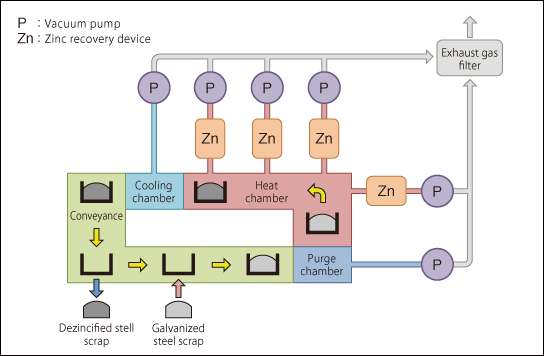

Vacuum dezincification equipment process flow

Device overview

- (1) Weighing machine: Weighs galvanized steel sheet (shredder material) automatically while it is being loaded into baskets.

- (2) Purge chamber: Evacuation is performed here before loading the workpiece to the heat chamber (constant vacuum).

- (3) Heat chamber: Heat is applied to evaporate zinc from galvanized steel sheet (shredder material).

- (4) Zinc recovery device: Evaporated zinc is deposited on a cooled surface and recovered.

- (5) Cooling chamber: The workpiece is transported from the heat chamber (constant vacuum) to the cooling chamber under a vacuum, the chamber is then charged with nitrogen, and the workpiece is cooled in a nitrogen atmosphere.

- (6) Furnace external conveyor: Unloads workpieces to and from the vacuum dezincification equipment, and conveys them to the turnover device.

- (7) Turnover device: Turns cooled workpieces over, and then removes the dezincified steel sheet (shredder material).

- (8) Vacuum pump: Evacuates the inside of the vacuum dezincification equipment furnace.

- (9) Activated charcoal filter: Exhaust gas produced during processing is passed through an activated charcoal filter before being released into the atmosphere.